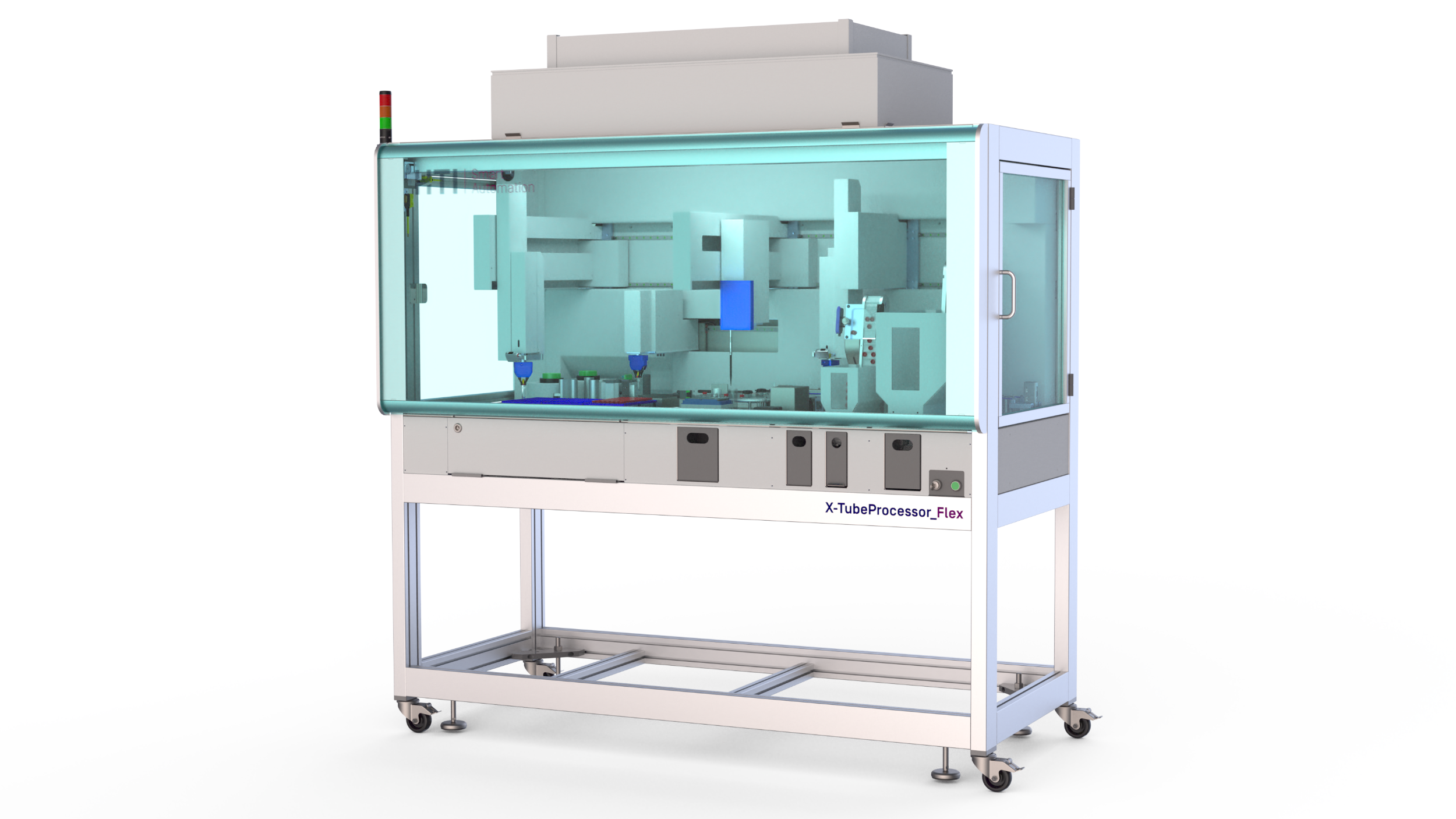

Ultra

When standard modules are no longer sufficient, we rely on the ultra solution

A high throughput systems for your flexible automated process

Pipetting, dispensing, labeling of tubes, labeling of screw caps, screwing, opening, IPC, sorting, storing and much more. and preferably at the same time. Our X-TubeProcessor®_Ultra supports your flexible process with the processing of up to 1,000 tubes per hour. Different modules can be used to handle up to 10 processes in parallel. HTI’s Ultra systems are characterized by universal application possibilities, high accuracy and compact design. The X-TubeProcessor_Ultra also shows maximum flexibility with micro screw tubes. You can use tubes or cyrovials from Sarstedt, LVL, Micronic, Matrix or other manufacturers.

The screwdriver and cap handler

The X-TubeProcessor®_Ultra automates the opening and closing of tubes. We offer solutions for various tube and screw cap sizes and types. Fully automatic feeding of tubes and screw caps via a tube or cap feeder is possible. Both screwed and open tubes can be fed to the unit as bulk material. The cap feeder can be optionally equipped with a color sensor. This checks the color of the caps and sorts out the wrong caps.

Dosing, pipetting and dispensing liquids

The tubes can preferably be filled sequentially with reagents. Depending on the requirements, several peristaltic and/or syringe pumps are available. The Syringe pumps are used for pipetting/dispensing of smaller filling volumes. Especially with very small liquid volumes, pipetting is very precise, so that the reproducibility of the results is ensured at all times. The change of pipette tips can be freely selected. Peristaltic pumps (peristaltic pump) are provided for dispensing larger volumes. It is possible to cool the output vessel (reagent vessel) and to integrate a weighing module for monitoring dispensing volumes.

Labeling Tubes

The X-TubeProcessor®_Ultra can be extended with a labeler module for labeling tubes and/or caps. Printing is done individually or in batches in the same way. The label information can be fed via the operating menu on the device or via a database connection. Various marking systems such as laser, thermal transfer or inkjet can be used. Of course, pre-printed labels can also be applied.

Feeding, Sorting & Storage

Do you need a whole rack storage or is individual tube feeding important to you? Or even a combination of both? The feeding as well as the final storage of the tubes can be done in bulk or in single or in a number of up to 50 racks in an automated rack storage system. Talk to us and together we will define your individual solution.

Barcode identification

Reliable traceability in the work process is possible at all times with our products. Barcodes can be read on racks and tubes and processed according to the stored requirements.

Sterile applications

We offer tube handling solutions also for sterile applications. For this purpose, the devices are equipped with special hoods, Hepa filters and laminar flow.

User interface:

The user-friendly and intuitive software runs on an external laptop or PC. Various criteria can be defined for editing the tubes and individual modules can be selected or deselected.

To start the machine, you can select the created jobs in an overview or alternatively enter them directly on the user interface. A menu guides you through the input steps. Jobs can be transmitted to the control software via an interface (SOAP- TCP/IP protocol).

Messages, malfunctions or news can be transmitted via an email output, among other things. In this way, you will be quickly and reliably notified of machining events even if you are not currently at the plant.

Requirements exceeded? Choose your suitable flexible tube and cap handling system from our X-TubeProcessor series.

Sort & Store

Identification

Label & Mark

Dispensing

Sterile applications

Tube & Cap Handling

Facts and figures

Up to 10 parallel processes

Serial and parallel processing

STERILE applications possible

Screwing / Opening

Dispensing

Peristaltic / Syringe Pumps

Labeling tubes and caps

Thermal transfer or laser printer

Barcode identification

Cap feeder

Tube feeder

Rack feeder

Torque control

InProcess Control

Requires compressed air

10

Up to 10 parallel processes

1000

Up to 1000 tubes / h

100

Up to 100 SBS racks

Footprint

150 x 150 x 200 cm up to 300 x 300 x 200 cm (l x w x h)

Let our specialists advise you!

We would be happy to discuss your application and automation needs with you:

Phone: +49 8092 2092-70 or e-mail: sales@hti-automation.com