All about

Tube Handling

Welcome to the

SLAS 2026 in

Boston!

February 7–11, 2026

Visit us at Booth 1532

Meet our SLAS team

Dr. Wolfgang Heimberg

Founder & CEO

Dr. Thomas Krüger

Managing Director

Alan Lakshmanan

Area Sales Manager

Bernhard Kleynmans

Software Developer

Reserve your personal time slot at SLAS 2026

Get individual advice on how to fully automate your tube handling workflows — tailored to your lab’s requirements, sample volumes, and throughput needs.

Automate your manual lab processes

Automate your Cap-Handling

High-precision decapping and capping for safe, reproducible workflows.

Automate your Labelling

Error-free tube labeling for any format — ideal for studies, workgroups, and high-throughput labs.

Automate dispensing / pipetting / aliquoting

Consistent quality and maximum efficiency for liquid handling workflows.

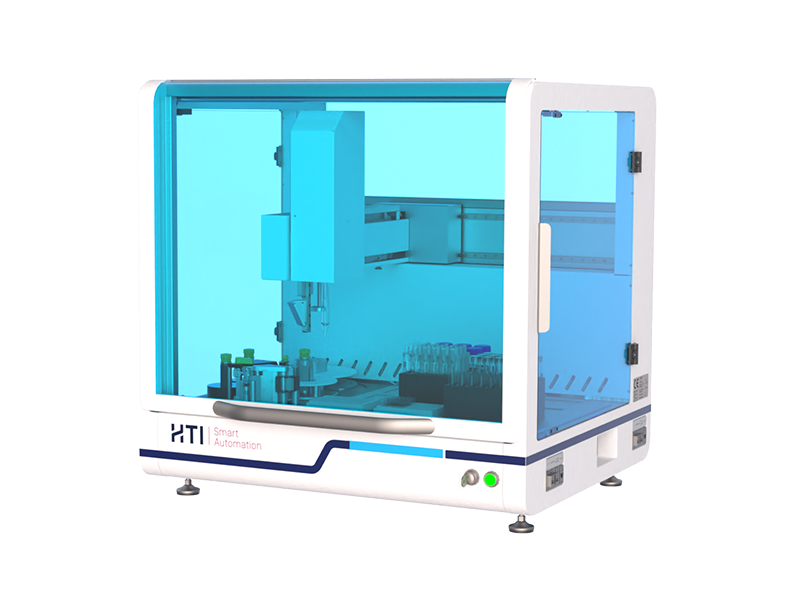

Our systems at SLAS 2026

Meet both systems live at Booth 1532 and experience how Sign and Smart 2.0 support accuracy, consistency and efficiency in modern laboratory operations

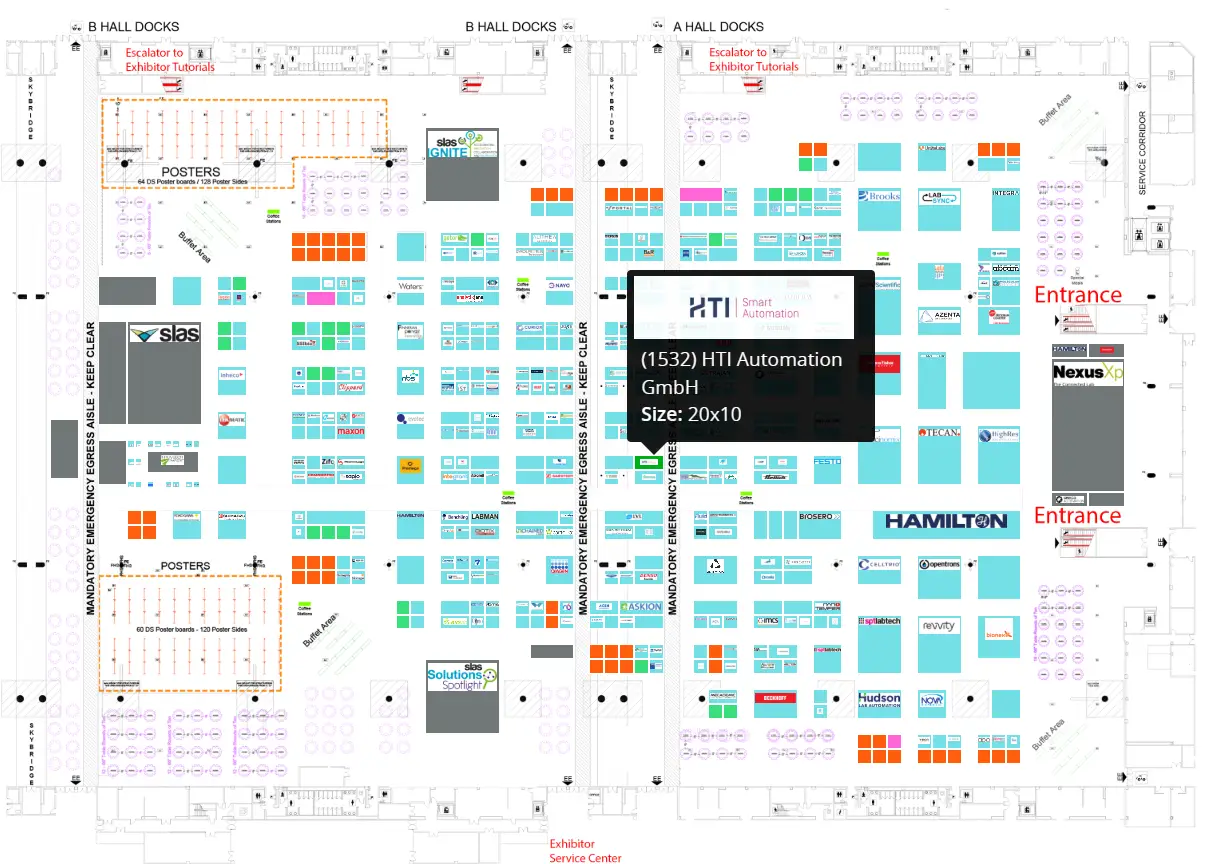

Location & Opening Hours at SLAS 2026

HTI at the SLAS 2026

HTI booth:

1532

Opening hours:

February 7 – 11, 2026

Sat. 7 – Tue. 10: 10:00 a.m. – 6:00 p.m.

Wed. 11. 9:00 a.m. – 1:00 p.m.

Location:

Boston Convention & Exhibition Center

Boston, MA, USA

About HTI Automation

For more than 20 years, HTI Automation has been redefining what is possible in laboratory and production automation – always in close collaboration with our customers. With deep engineering expertise and a strong commitment to quality, we deliver solutions that make your workflows faster, safer, and more efficient.

Why leading laboratories rely on HTI:

Experience the X‑TubeProcessor® platform

Switch from ergonomic strain and repetitive manual work to fully automated tube processing.