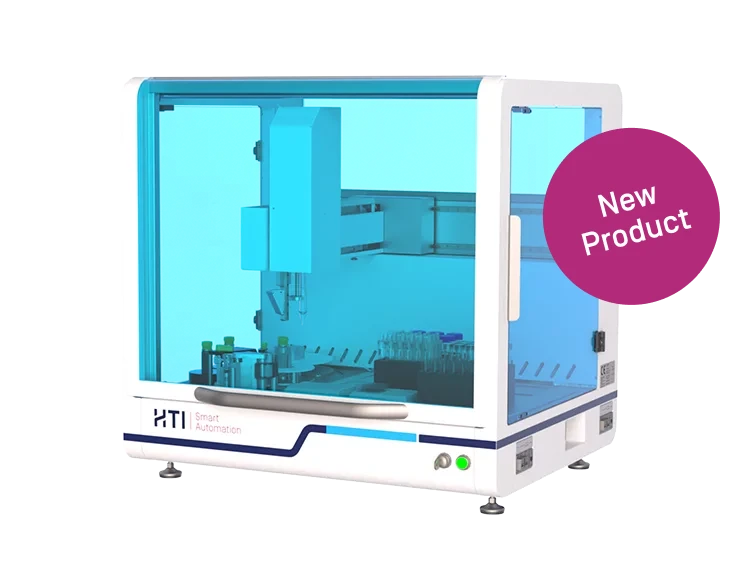

Basic

The first step to automate your tube processing

Your time is precious

The X-TubeProcessor®_Basic opens and screws micro screw tubes and is the ideal system foruserslooking for simple automation for tube processing. The Basic relieves the burden of monotonous manual work, prevents chronic overload syndromes and frees up time for other tasks. The Basic is functionally expandable through various modules.

Screwing and opening micro screw tubes

In the standard unit, the screw caps (caps) are fed as bulk material, and the tubes must be pre-inserted in racks. The time-consuming manual application of the caps is no longernecessary. A tube turning gripper removes the caps from the cap feeder and screws the tubes together.

We offer solutions for micro screw tubes from different manufacturers

e.g. Sarstedt, SSI, Thermofisher etc.

The Basic offers various functionalities for process stabilization:

- Torque control

- Space detection

- Tube and cap presence control

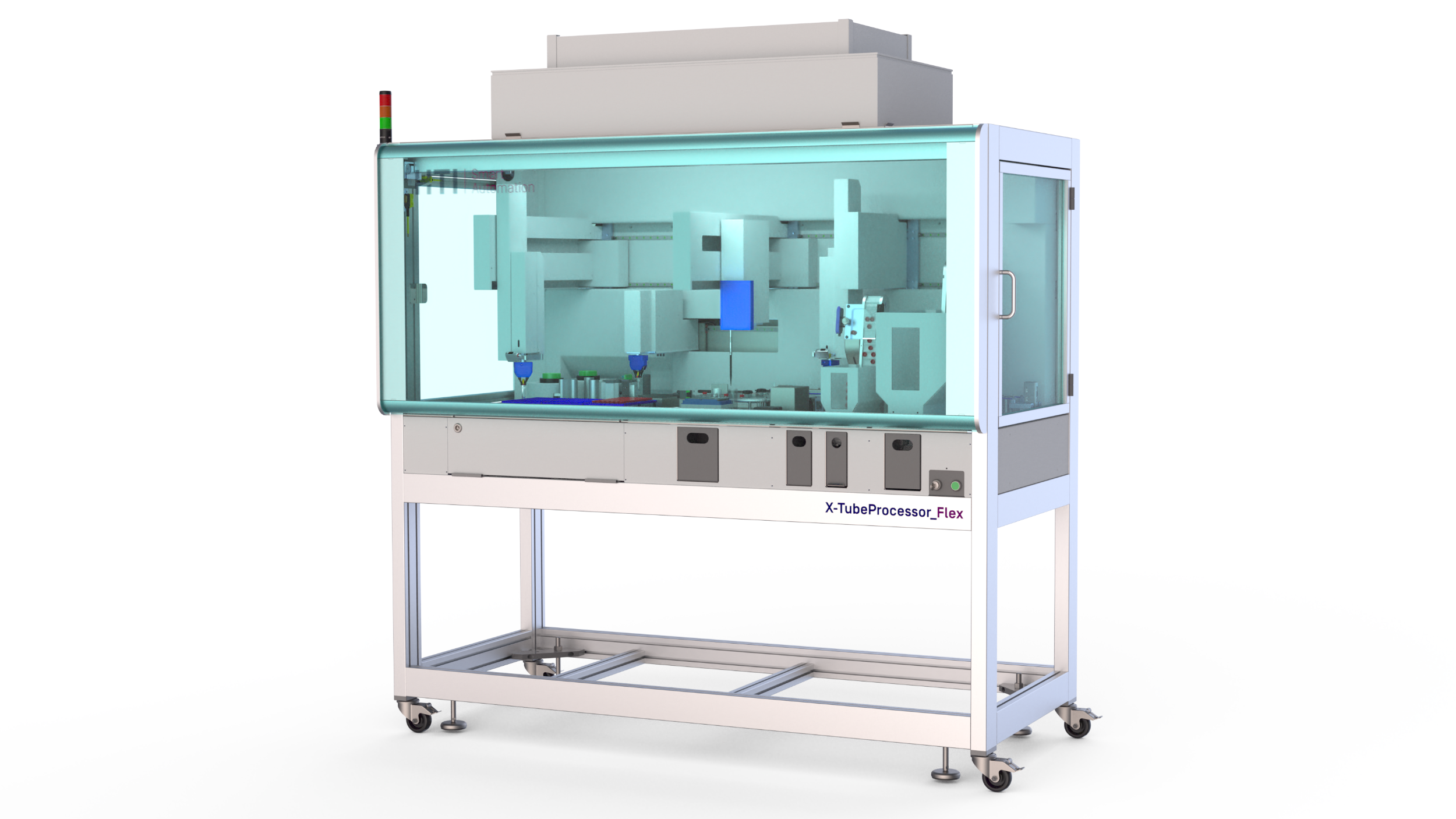

Tubes labeling

Expand the X-TubeProcessor®_Basic with a labeling module for precise application of your labels. User-friendly software is available for designing the label layout. Transfer your data via a USB stick, an external computer or connect the printer directly to your network.

Based on the same housing concept, the Basic is also available as a pure labeler with or without a tape module.

Sorting & Storage

In the X-TubeProcessor®_Basic, one rack with 96 tubes or alternatively 2 SBS racks with 48 tubes each can be processed as standard. To further increase your walkaway time, the device can be expanded with a band module. Thus, up to 6 racks can be processed without reloading.

Tube & Cap Handling

Label & Mark

Sort & Store

Let our specialists advise you!

We would be happy to discuss your application and automation needs with you:

Phone: +49 8092 2092-70 or e-mail: sales@hti-automation.com