Our products

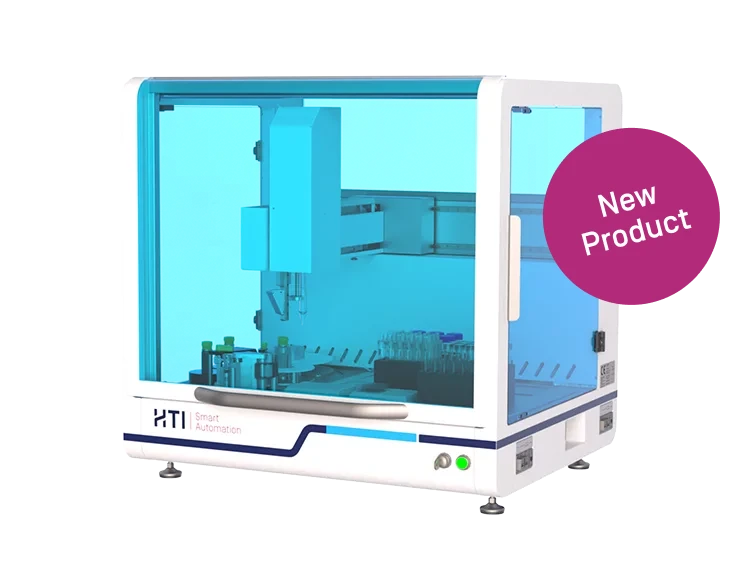

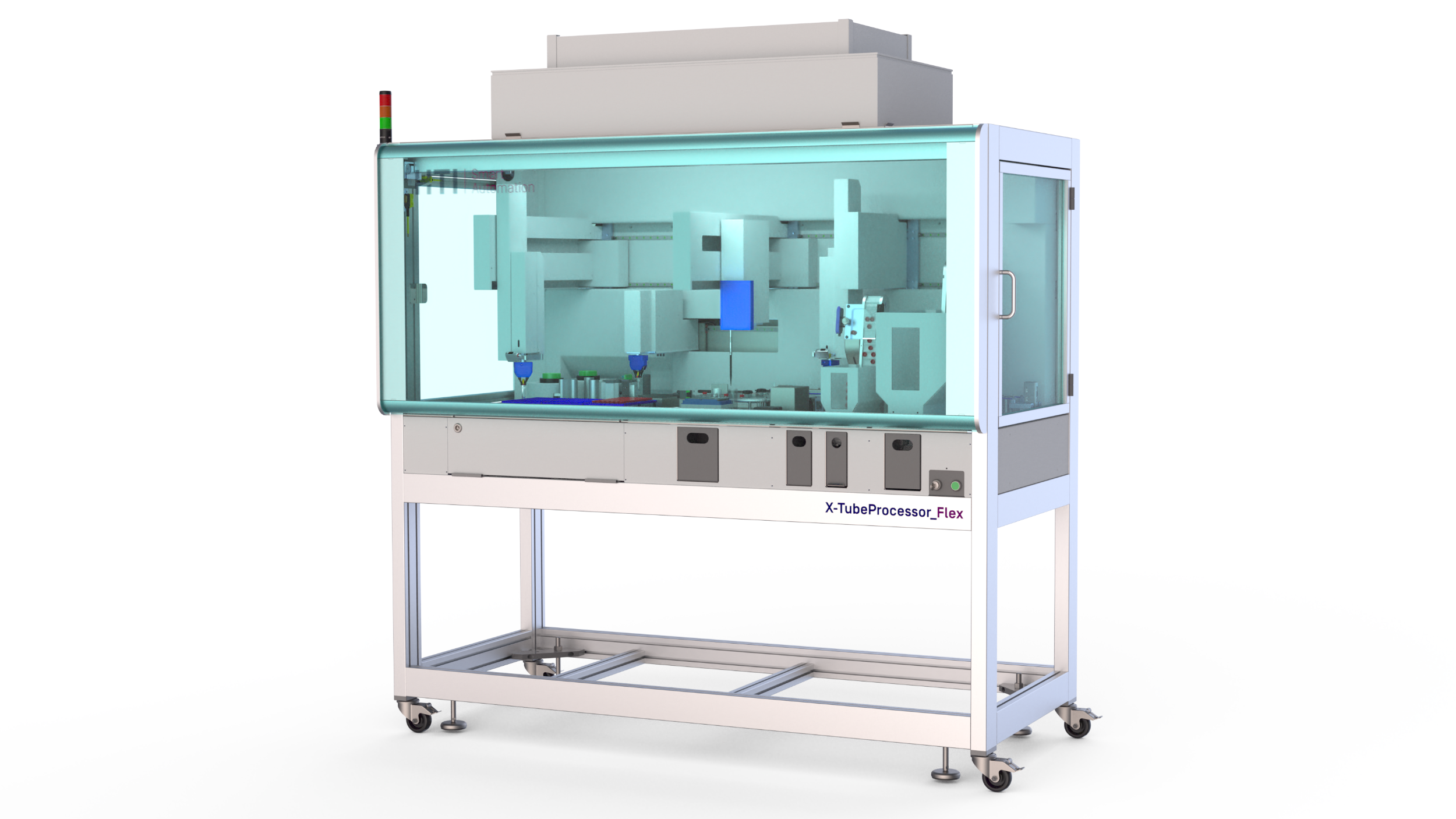

Tube Handler:

X-TubeProcessor® Series

Your time is precious – learn more about the possibilities of automated tube & liquid handling.

X-TubeProcessor® Series

Your time is precious – learn more about the possibilities of automated tube & liquid handling.

Switch from ergonomically strenuous and monotonous manual work to fully automatic processing of your micro screw tubes.

Basic, Smart, Flex or Ultra –

Depending on the degree of automation, we have the right device for you.

Function modules of the X-TubeProcessor® series

Available modules for the automation of tube processes

- Bulk material feeding

- Screwing

- Open

- Positioning

- Color recognition (optional)

- Torque control

Tube and cap handling

Our products automate the opening and closing of tubes. We offer solutions for various tube and screw cap sizes and types. The devices are scalable in automation level, throughput, size and complexity. Various tasks for processing tubes are automated.

- Highest accuracy

- Small to large volumes

- Different viscosities

- Sterile or contamination-free (optional)

- Liquid Level Detection and InProcess Control

- Recording or monitoring of the filling volumes

Dispensing

The tubes or/and vials are filled with reagents in parallel or sequentially. Typical dispensing volumes are in the range of 10 µl to > 2 ml per tube. If necessary, the reagents are stored refrigerated. Various solutions for process monitoring are offered and implemented, ranging from level detection to the determination of dispensing volumes by weighing.

- Labeling & Marking

- Tubes & Caps

- Thermal transfer as standard

- Laser / Inkjet (optional)

- Labels for storage up to -196°C

- Database connection (optional)

- Serialization

- Barcode and 2D matrix

- Reliable and wrinkle free

Labeling & Marking

Our equipment labels tubes and screw caps of different sizes and with different labels. In addition, we offer the possibility of printing tubes and caps directly. Printing is done individually or in batches in the same way. The respective marking technology is based on the needs and customer requirements.

- Presentation of the tubes in racks or as bulk material

- Editing individual racks

- Rack storage (optional)

- Presentation of the screw caps as bulk material

- Output of the tubes in racks or boxes

Sorting & Storage

HTI products enable small and high throughput. For high-throughput systems, among other things, the intermediate storage of tubes and racks in the equipment is also realized. If required, the Tubes and Caps are presented in bulk and dispensed in racks or in bulk.

- Code processing of racks, tubes and caps

- Capture 1D and 2D codes

- Verification Human Readable Infos with OCR (coming soon)

- Verification of the information with database matching

Identification

Reliable traceability in the work process is possible at all times with our products. Barcodes can be read on racks, tubes and caps and processed according to the stored requirements.

- Separation of storage and process areas

- Process areas with measures for sterile conditions

- Systems are supplied with appropriate documentation

Sterile applications

We offer tube handling solutions also for sterile applications. For this purpose, the products are adapted with special hoods, Hepa filters and/or laminar flow systems.

Let our specialists advise you!

We would be happy to discuss your application and automation needs with you:

Phone: +49 8092 2092-70 or e-mail: sales@hti-automation.com