Individual solutions

When standard solutions are not sufficient, we develop solutions tailored to customer requirements.

Individual solutions

When standard solutions are not sufficient, we develop solutions tailored to customer requirements.

Experience Measured

Process competencies

Our core competencies for the standardization of laboratory and production processes.

- Handling of Tubes & Caps

- Screwing

- Discovery

- Separate & Position

- Pick & Place

- Color recognition

- Torque control

Tube & Cap Handling

Our products automate the opening and closing of tubes. We offer solutions for various tube and screw cap sizes and types. The devices are scalable in automation level, throughput, size and complexity. Any tube processes are automated.

- Highest accuracy

- Low to high volumes

- Various liquids

- Sterile or contamination-free

- Liquid Level Detection and InProcess Filling Control

- Dispensing in 96/384/1536 MPT

Liquid Handling

The tubes or/and microtiter plates are filled with reagents in parallel or sequentially. Typical dispensing volumes are in the range of 1 µl to > 2 ml cavity. If necessary, the reagents are stored refrigerated. Various solutions are offered and implemented for process monitoring starting from level detection up to the determination of dispensing volumes by weighing.

- Labeling & Marking

- Tubes & Caps

- Thermal Transfer / Laser / Inkjet

- Labels for storage up to -180

- a.o. direct marking on tubes

- Database connection

- Serialization

- Barcode and 2D matrix

- Reliable and wrinkle free

Labeling and marking

Our devices label and mark tubes or/and screw caps in different sizes and with different labels. Printing is done individually or in batches in the same way. The respective marking technology is based on the needs and customer requirements.

- Single dosage

- Parallel dosing e.g. in corrugated sheets

- simple, fast and reliable

- Filling service for synthesis columns etc.

Powder dosage

We offer solutions for easy and fast dosing of free-flowing powder, e.g. for filling of synthesis columns and similar.

- Capture 1D & 2D codes on tubes and plates

- RFID identification and localization

- Part and sample detection and tracking

- Scan and detect

Identification

Reliable traceability in the work process is possible at all times with our products. Barcodes can be read on racks and tubes and processed according to the stored requirements.

- Gripper systems for parts and plates

- Rotary gripper for transport and positioning

- Conveyor systems for plates, carriers and bulk materials

- Bulk material singulation and positioning

Transport and storage

HTI offers systems for separating, transporting and storing individual components – such as tubes – plates or/and carriers and cardboard boxes. Various gripper and belt systems are available for this purpose, among others. Storage is in chaotic or orderly warehouses.

HTI development process

We offer application-oriented full service engineering

Processes

#TUBE-HANDLING

#LIQUID-HANDLING

#DISPENSING

#PIPETTIES

#DOSING

#FILL

#SWITCH

#DECLARATION

#LABELN

#ETIKETTIER

#CONCEPT

#STORAGE

#STERILE APPLICATIONS

#FILL

Special processes

#POWDER DOSING

#STORAGE SYSTEMS

#PRODUCT TRANSPORT

#LABORATORY AUTOMATION

#WASHINGPROCESSES

#TEMPERATE

#COOLINGPROCESSES

#DEVICEDEVELOPMENT

#PROTOTYPING

#AUTOMATION

#LABORATORY CENTRIFUGES

#LAB SCREWDRIVER

#LABELLER

#FILLING LAYERS

Industries – Applications

#LIFE-SCIENCES

#REAGENTS PRODUCTION

#KIT PRODUCTION

#SAMPLEPREPARATION

#OLIGO SYNTHESIS

#PHARMA

#PACKAGING

#DEVICEDEVELOPMENT

#DEVICEPRODUCTION

#SOFTWAREDEVELOPMENT

#ENGINEERING SERVICES

Reference projects

Selected projects for individual solutions

Liquid handling & capping solutions

Building on the wide-ranging experience with our X-TubeProcessor® equipment series, we have combined various systems for customers for classic liquid handling with downstream production processes such as screwing and labeling. These systems map the complete kit manufacturing workflow.

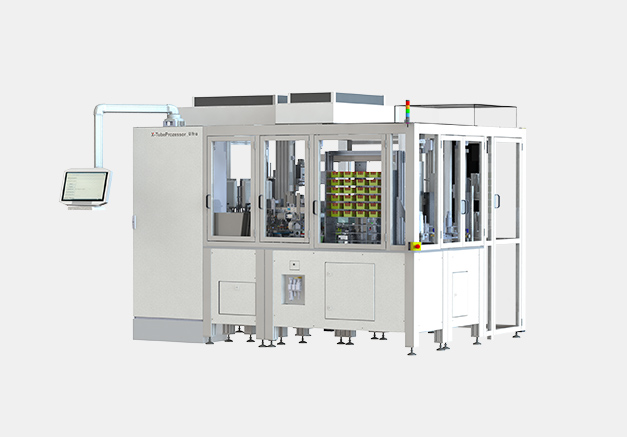

Multipurpose platforms

We offer fully automated and highly integrated solutions, for processing, organization and storage of samples or cavities. The customized solutions include intelligent robotics, various functional modules (e.g. liquid handling), transport systems, measuring equipment, data processing and control software.

Multi-dispenser

With the development and production of a multi-dispenser, a platform for coating membranes with special proteins was realized. The system is used by DIAGAST, a well-known French company for production.

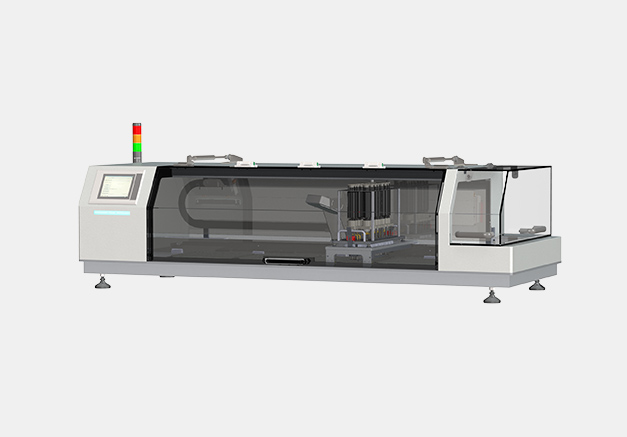

X-TubeProcessor®_Ultra

Our comprehensive know-how in tube and liquid handling is exemplified by our X-TubeProcessor® product family. Established technologies, such as liquid handling, are combined and automated with other individual processes in a coherent overall concept. The Ultra is used by a customer for fully automated reagent filling in production.

Let our specialists advise you!

We would be happy to discuss your application and automation needs with you:

Phone: +49 8092 2092-70 or e-mail: sales@hti-automation.com