Efficient liquid handling in the laboratory: Automated product filling, precision and applications at a glance

High-precision automated liquid handling for product filling: a comparison of syringe pumps vs. peristaltic pumps

In the laboratory world, efficient automated liquid handling is crucial. The devices and instruments used for this purpose are among the indispensable classics of laboratory equipment and automation.

There are numerous manual and automated systems available on the market that support liquid handling in a wide range of applications. Modern laboratory machines for liquid handling are characterized by their ability to meet a wide range of different requirements and applications with maximum flexibility and precision.

This article provides insights into technologies and solutions for laboratory technology, from pump selection to process design:

- Continuous vs. batch operation:

How does the production method influence test kit manufacture? - Requirements for efficient dispensing:

Sterility, throughput rate and precision - Syringe vs. peristaltic pumps:

Which system suits your liquid dosing requirements?

Increasingly, however, solutions are being sought that not only meet the typical requirements of automated liquid handling, but also take into account the conditions of production processes.

In many cases, individual containers are used as product containers. The X-TubeProcessor® series specially developed by HTI is designed to enable the automated processing of screw tubes in these processes. Some of the processes that can be automated with our devices are shown in the graphic below:

Examples of automated laboratory processes

1. process design in automated test kit production: continuous vs. batch operation

The requirements for the production process for the automated manufacture of test kits are diverse. It is crucial to ensure sterile conditions and strict regulatory requirements, including individual sample tracking and dedicated in-process control (IPC).

In automated production, a basic distinction is made between two operating modes: continuous operation and batch operation.

Continuous processes are preferable when large quantities are processed with only a few product changes, as is often the case in pharmaceutical production. This has the advantage that the set-up times that are typical for cleaning and refilling in batch processes are eliminated, making the processes more economical.

Discontinuous batch operation is preferable for the production of smaller or limited manufacturing quantities, especially if different reagents or product vessels are frequently used. When changing products, appropriate measures must be taken to ensure product quality and sterility.

Our HTI standard devices are designed exclusively for batch operation and are also suitable for filling tasks in small and medium-sized laboratories in terms of size, throughput and costs. This ensures that the requirements for the automated production of test kits can be met efficiently.

2. efficient dispensing in automated filling processes: Requirements for precision, sterility and throughput rate

Automated liquid handling with integrated labeling, filling and screwing

Dispensing, i.e. the distribution of liquids from a large container into many smaller transport containers, is an essential function in automated filling processes. The requirements are very similar to typical liquid handling tasks and include aspects such as avoiding contamination, ensuring sterility and filling precision.

With regard to automated production, it must also be ensured that it meets the requirements in terms of planned throughput rates and product stability. The duration of the filling process plays a decisive role in the throughput rate, while long process times may require active cooling of the output containers and the products filled and stored in the appliance to ensure product stability. It should be noted that in most cases a single reagent must be distributed over many containers, which is why large initial containers are necessary.

Torun Ekblad, COO of Mabtech

Case Study Liquid Handling:

Increased efficiency in laboratory kit assembly and development of immunoassays with the FLEX 2.0: Automated storage, filling and labeling.

3. comparison of syringe pumps and peristaltic pumps for automated filling

Two common pump types are available for automated filling: syringe pumps (so-called syringe pumps), which are already familiar from liquid handling machines, and peristaltic pumps.

Syringe pumps are characterized in particular by their

high dosing accuracy,

even with small volumes. They are often used when only a single reagent needs to be dispensed. In such applications, syringe pumps are used as direct dispensers, which means that the dispensing cannula does not need to be moved, making dispensing very fast. However, the pistons and cylinders of the pump tend to become contaminated, which is why extensive cleaning or decontamination is required, especially before the start of production or a reagent change.

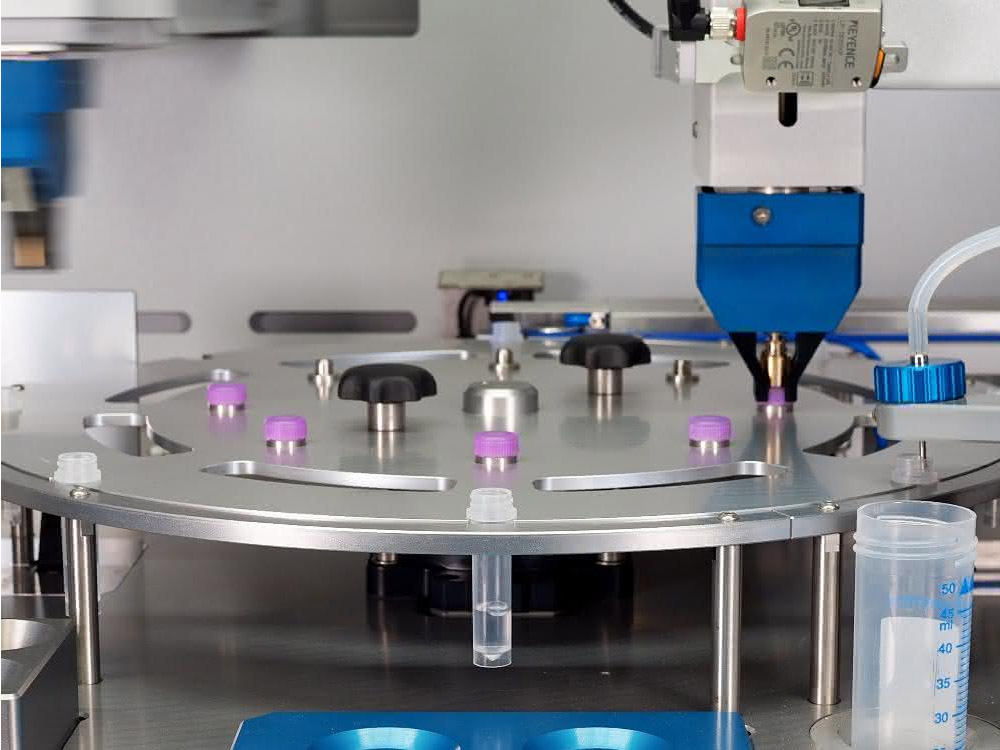

Example of filling with syringe pump and interchangeable tips on the X-TubeProcessor_Flex

In flexible dosing applications where, for example, reagents are changed in batches, syringe pumps are often used as air displacement pipettors with disposable tips. The aspiration and dispensing of the reagent is separated in time and space, which means that the pipette tips have to be moved between the storage vessel and the target vessel. This leads to longer process times and increased effort in robotics control, which in turn leads to higher costs. Although the use of disposable tips prevents contamination of the pump and the transfer of reagents, there are limitations if the reagent to be dispensed is placed in a large, deep vessel, as the disposable tips cannot be immersed in the vessel to any depth.

Peristaltic pumps offer a sensible alternative, especially in filling processes. They allow simultaneous aspiration and dispensing of the reagent without having to move the dispensing cannula. These pumps are characterized by

fast filling

the

avoidance of pump contamination

and – if a new pump tube is used for each filling process – the prevention of the transfer of reagents from batch to batch. The total costs for peristaltic pumps are generally lower than for syringe pumps.

Precise dispensing with peristaltic pump and automatic Walltouch

4 Precise dosing of liquids: Syringe pumps and peristaltic pumps in comparison

Syringe pumps are characterized by a clear design with pump pistons and cylinders that are moved by a precise drive. The various properties of the liquids to be dispensed are taken into account by predefined liquid classes. This leads to very precise dosing (accuracy).

Peristaltic pumps also have a precise drive. However, their dosing behavior is less precise due to the natural, not always exact hoses. To solve this problem, a calibration is carried out before each dosing process. All systematic influences such as the properties of the liquids, pumps and hoses are recorded. The actual dispensing quantities are compared with the target quantities and then corrected via the pump control system. Calibration significantly reduces systematic dispensing errors. Only a temperature- and usage-related error of a few microliters remains, which is negligible for most filling tasks, especially for larger doses. HTI’s automatic filling machines are equipped with appropriate functions for quick calibration.

The precision (dispersion) of dispensing describes the statistical error that is often caused by the application itself and not by the devices. One of the causes is irregular drop formation at the pipette tips or dosing cannulas. As far as possible for reasons of contamination, precision can be improved by so-called “surface touch” or “wall touch”, which means that the pipette tip dips into the liquid or touches the vessel wall in the target liquid container. Automated processor systems also offer appropriate solutions for this.

Conclusion for the automation of liquid handling

The automation of liquid handling in filling processes differs from conventional liquid handling applications in terms of the specific conditions of process automation.

| Feature | Syringe pumps | Peristaltic pumps |

|---|---|---|

| Dosing accuracy | High accuracy, even with small volumes | Precise dosing, occasionally requires calibration |

| Intended use | Individual reagent dosing | Fast filling of larger volumes |

| Contamination and cleaning | Susceptible to contamination, requires extensive cleaning | Low risk of contamination, easy replacement of the hose |

| Batch operation | Less suitable for frequent product changes | Well suited for various reagents and product changes |

| Total costs | Higher due to the need for disposable tips | Generally lower total costs |

| Field of application | Precise dosing of small volumes | Fast and contamination-free filling of larger volumes |

The decisive difference is that, as a rule, only one or a few reagents are distributed over a large number of production vessels. This requires a high process speed in order to achieve the required throughput, as well as the need for process control.

When precision is required, especially for small dispensing volumes, syringe pumps are the preferred solution. On the other hand, peristaltic pumps offer advantages for fast filling and preferably larger dispensing volumes.

In the processors of the X-TubeProcessor® series from HTI, both pump systems can be used for dispensing as required. The user has the option of selecting the appropriate pump for each filling operation.

X-TubeProcessor®_Smart

Small footprint:

Tube and liquid handling

Laboratory automation in the smallest of spaces: Discover the compact and cost-saving automation solution for opening, filling, labeling and closing microscrew tubes.

Core functions:

- Labeling & marking

- Screwing and unscrewing

- Peristaltic pump

- Air displacement pipette (ADP)

- Sterile working due to HEPA filter

- Edit process steps in parallel

- Cap- / TubeFeeder

- Data management

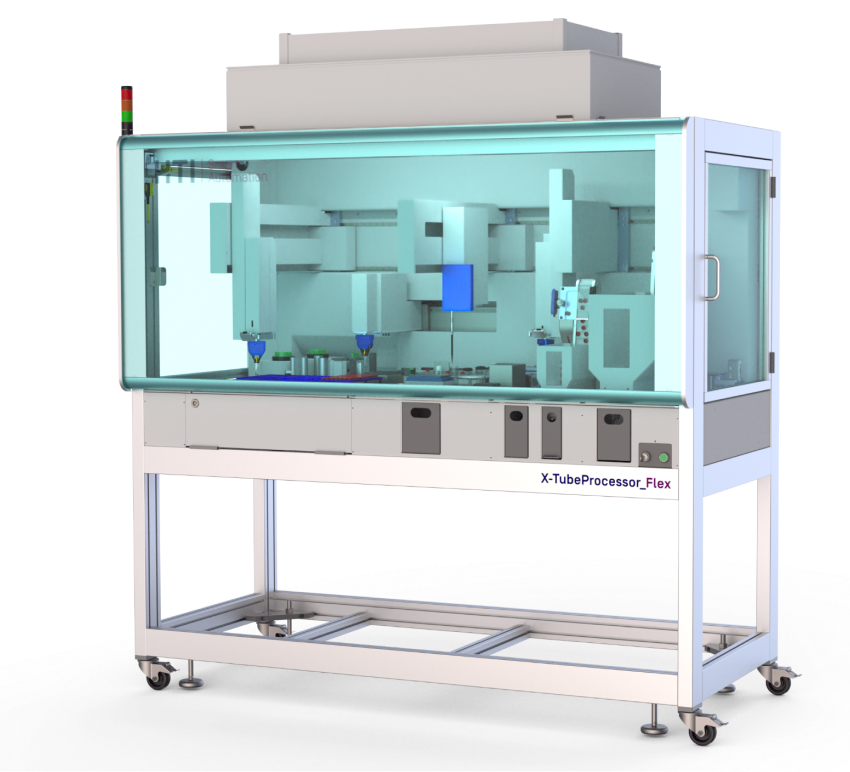

X-TubeProcessor®_Flex

High throughput:

Tube and liquid handling

Automate your tube processes in parallel with high throughput:

With its standardized, freely combinable modules, the

X-TubeProcessor ® _Flex, the simple automation of your individual processes.

Increase your walkaway time and benefit from flexible process customization.

Core functions:

- Labeling & marking

- Barcode identification

- Screwing and unscrewing

- Peristaltic pump

- Air displacement pipette (ADP)

- Sterile working due to HEPA filter

- Edit process steps in parallel

- Cap- / TubeFeeder

- Cooling

- Data management