Laboratory automation within smallest space

Tube handling has never been easier: Discover the compact and cost-saving automation solution for opening, dispensing, labeling and sealing micro screw tubes.

Buchen Sie eine kostenfreie Beratung

Buchen Sie jetzt einen Termin und lassen Sie sich von unseren Experten individuell beraten.

Erleben Sie, wie Tube- und Liquidhandler Ihre Arbeitsprozesse revolutionieren können.

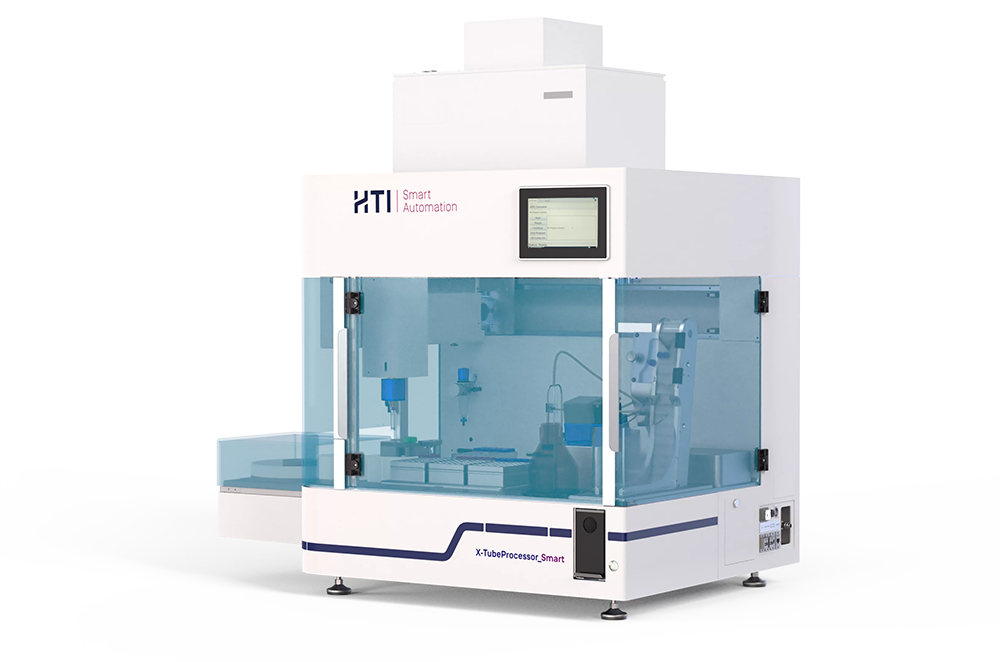

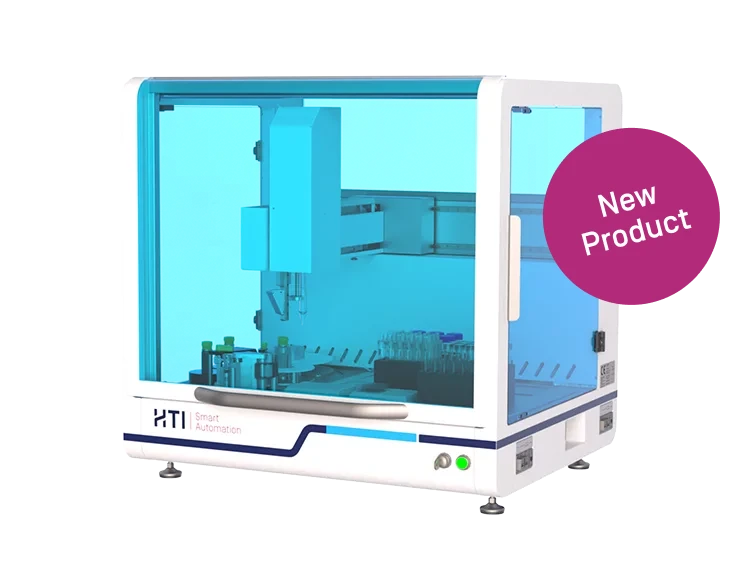

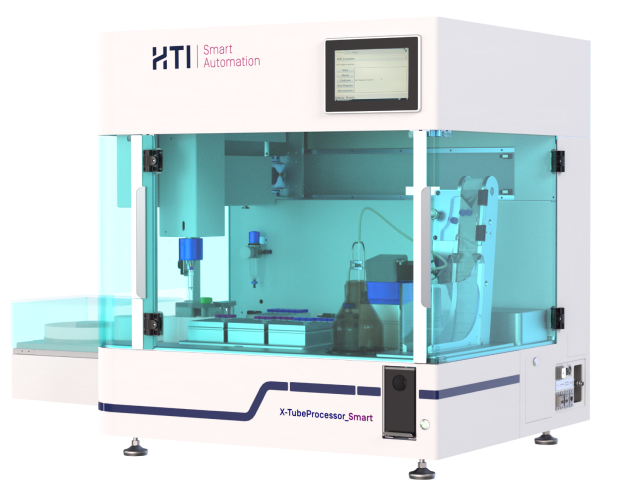

X-TubeProcessor®_Smart

The compact all-rounder for your laboratory

Longer walkaway time

thanks to processing of up to 6 racks

Reproducible, safe and efficient processes

due to sensor-stabilized and time-saving machining processes, as well as sterile working environment thanks to HEPA filter

Adaptation to a wide range of processes and different production volumes

thanks to its various processing capacities and individual workflows.

No interference with laboratory processes thanks to compact size and quiet operation

Easily expand your laboratory with minimal space requirements and short delivery time of the device

(when using Sarstedt tubes)

Technical data

Supported tubes

Sizes:

from 0.5 to 2 ml

Diameter:

7 mm – 22 mm

Heights:

max. 65 mm, (2.559″)

Manufacturer: *

Sarstedt,

SSI,

Biozyme,

Greiner,

VWR,

Thermo Fisher Scientific,

Nunc

*ask us if you need other tube types – together we will find a solution.

Speed and capacity

Speed:

up to 370 tubes per hour

Stock micro screw tubes:

576 tubes

Storage of microvials:

1152 Tubes

Rack Capacity:

6 SBS racks

(customized racks according to technical evaluation)

Dimensions and weight

Height:

84 cm, (33.2″)

115 cm, (45.24″) with HEPA filter

Depth:

73 cm, (28.86″)

Width:

82 cm, (32.40″)

107 cm, (42.28″) with labeling module

Weight:

Without labeling module: approx. 72 kg, ( 159 lbs)

With labeling module: approx. 85 kg, (187 lbs)

With labeling module and HEPA filter: 95 kg, (209 lbs)

Function modules of the _Smart

Available modules in _Smart for the automation of your tube processes

Screwing and uncapping micro screw tubes

The Smart automates the opening and closing of tubes. The devices are specially designed for 0.5 … 2.0 ml Sarstedt Tubes. The screw caps (caps) are fed in bulk, the tubes in racks. A tube rotary gripper picks up the caps from a cap feeder and screws the tubes with a defined torque.

Dispensing of liquids

An optional dispenser module based on a peristaltic pump enables precise, sequential filling of the tubes with reagents. Typical dispensing volumes are in the range of 25ul … 2,000 μl.

The Smart allows easy and quick cleaning of the interior.

Labeling Tubes

Expand the X-TubeProcessor®_Smart with a labeling module for precise application of your labels. User-friendly software is available for designing the label layout. The individual data can be fed via the user interface on the device or via a database connection.

Sort & Store

Your employees’ time is precious. The Smart allows a sufficiently large walkway time. Automated processing takes place in up to 6 SBS racks with 48 tubes each without further user intervention.

“The most important criterion for our business lies in the quality and reproducibility in the manufacture of our products. We were looking for a compact device, an all-in-one solution that would perform the filling of our wash buffers reliably and in the perfect walk-away time for us – and we found it in the SMART.”

Dr. Martin Käsemann,

COO PreOmics

Increase the capacity and process reliability of your laboratory through automation.

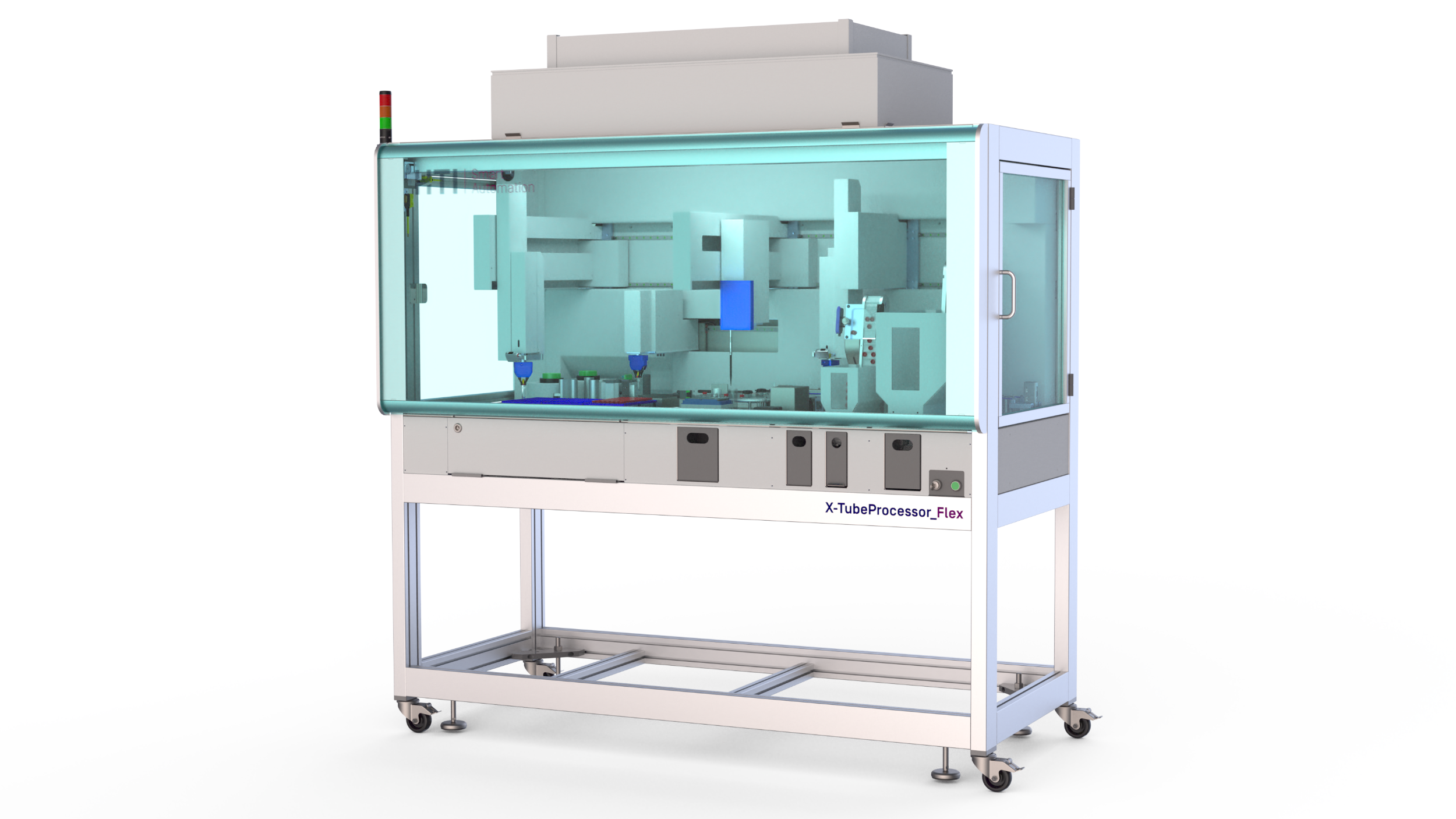

The Tube and Fluid Handling System is a comprehensive-automated solution designed to optimize tube handling, fluid transfer, and sample processing in a variety of laboratory applications.

Service and support –

Acting instead of reacting

Avoid downtime in your operation: As part of a customized service contract, we proactively maintain your products via routine on-site and remote maintenance. In addition, our training courses teach you everything you need to know as a user about the proper handling of your device.

We supply: Labels, racks and other laboratory consumables.

The partner at your side: HTI is a specialist for the automation of laboratory tubes. And this for 30 years. We not only take care of our machines, but also advise you and supply you with the right materials for your processes.

The compact all-rounder for your laboratory

From opening to closure: the X-TubeProcessor®_Smart relieves

your employees from having to work manually with micro screw tubes.

Set up to six racks of micro-screw tubes, press “Start”, done: processing tubes with the X-TubeProcessor®_Smart is that easy. Despite its compact size, the device is a full-blown automation solution that can be flexibly adapted to a wide range of processes and production quantities. This makes the X-TubeProcessor®_Smart suitable for more demanding applications even where space is limited.

The X-TubeProcessor®_Smart not only ensures that your liquids are filled in exactly the right quantity and quality, saving time and resources. It also frees your staff from manual pipetting and the associated risks: contact with potentially hazardous substances, human error, chronic stress symptoms (e.g. repetitive strain injury syndrome). Instead, your employees are deployed where they can develop their full potential.

HTI – Your partner in laboratory automation

+ 20 years

Experience in the biotechnology sector

+ 1100 devices and equipment developed and produced

Quality management according to DIN ISO 9001

Engineering Made in Germany – International Service Network

Let our specialists advise you!

We would be happy to discuss your application and automation needs with you:

Phone: +49 8092 2092-70 or e-mail: sales@hti-automation.com