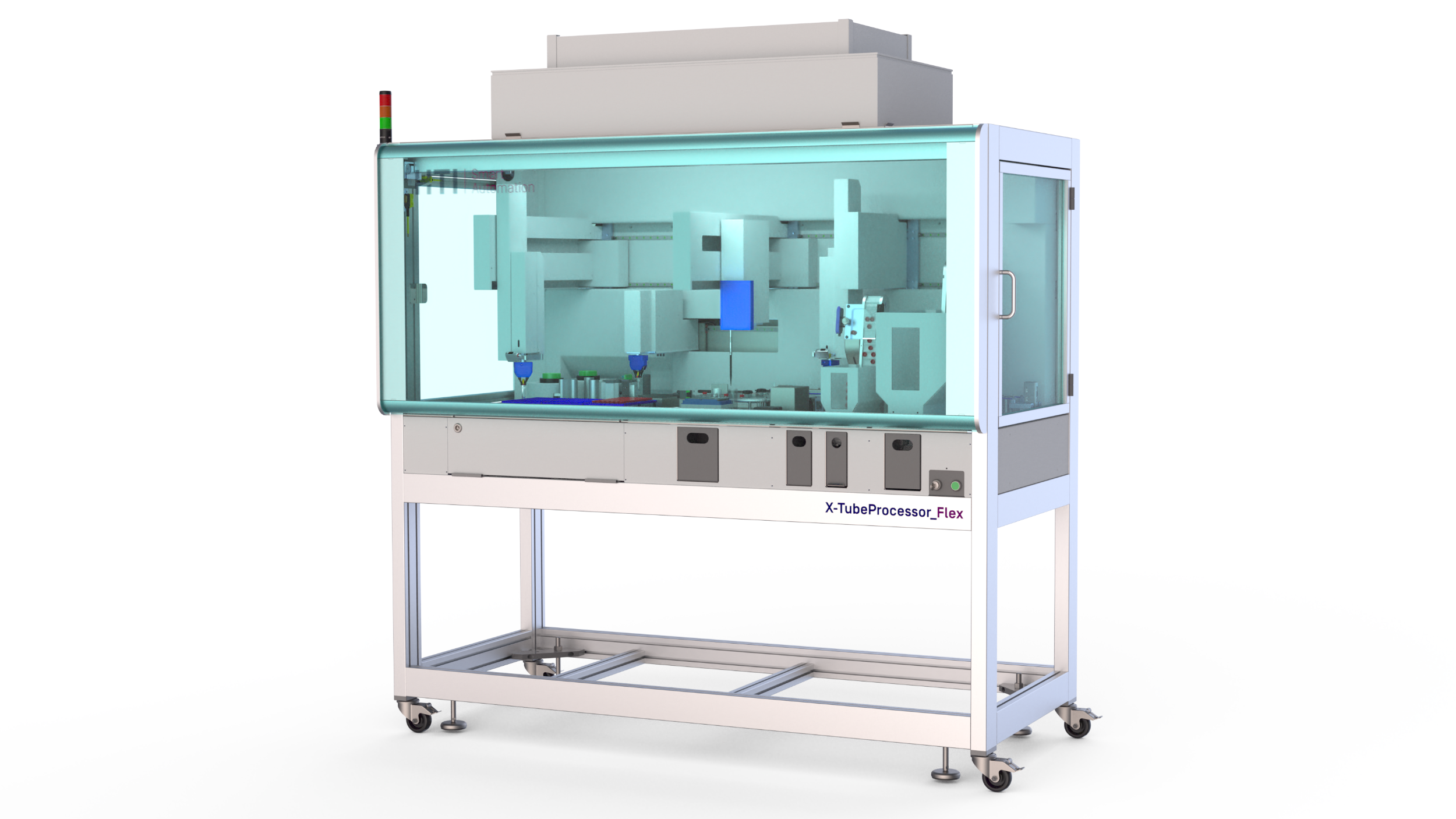

X-TubeProcessor®

Proceed

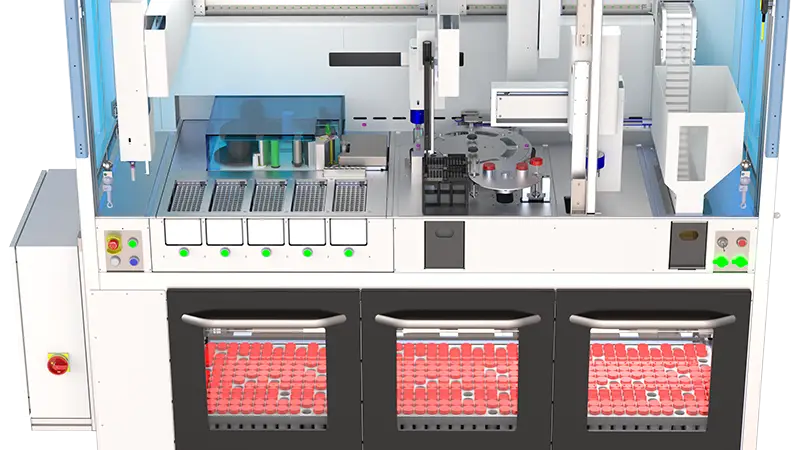

Fully automated filling systems for your laboratory

More productivity. More precision. Less effort. The X‑TubeProcessor®_Proceed — the new system based on the X‑TubeProcessor®_Flex — is specially designed for the production and filling of biomolecules.

From order receipt to the finished customized product, Proceed automates your filling processes – safely, efficiently, and around the clock.

This will enable you to enhance product quality, reduce sources of error, and significantly reduce the workload on your team.

Automation of complex filling processes from A to Z

With the X-TubeProcessor®_Proceed, you can automate demanding filling processes for RNA, DNA, peptides, proteins, and other biomolecules – from order to finished product. The system controls the entire workflow without manual intervention and documents every step seamlessly for audits and quality assurance.

Here’s how the X‑TubeProzessor®_Proceed works step by step:

Digital order processing & material testing

Orders are transferred directly from ERP or LIMS, and material availability is checked in real time.

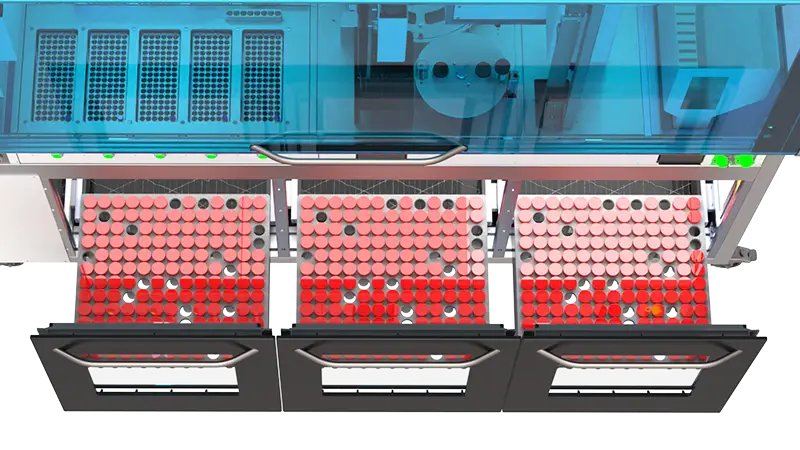

Automatic removal from refrigerated storage

Up to 450 sample vessels (50 ml) are managed at a controlled temperature and removed with precision.

Precise dispensing & filling with screw connection

Precise dosing up to 350 tubes/hour, fully automatic opening and closing.

Integrated labeling

600 dpi printing of product data, lot number, expiration date, and other customer-specific information with integrated validation of printed labels.

Digital documentation & traceability

Every step of the process is automatically recorded – ideal for audits.

Finished products can be removed at any time

The drawer system allows the filled and labeled tubes to be removed continuously without interrupting the production process.

All components for end-to-end automation

Result: Highest product quality, fewer errors, significantly lower costs, and easier audits and inspections.

Practical example:

Mabtech relies on HTI for maximum automation

In the video, Mabtech, a Swedish developer of immunoassays, reports on how the X‑TubeProcessor®_Proceed is revolutionizing filling.

Before: Time-consuming order verification, manual material removal, and high risk of errors.

Today: Electronic order processing, precise sterile filling, automatic labeling, and complete digital documentation – around the clock.

Areas of application:

For laboratories and production environments with high quality requirements

The X-TubeProcessor®_Proceed is ideal for companies that …

Advantages of laboratory automation with Proceed

Technical data & performance characteristics of the X‑TubeProcessor®_Proceed

Info Download

Performance:

up to 350 tubes/per hour

up to 1.000 tubes per batch

Dimensions and weight

Dimensions:

approx. 267 × 118 × 210 cm (W x D x H)

Approx. 105.1″ × 46.5″ × 82.7″ (W × D × H)

Weight:

approx. 450 kg

Approx. 992.08 lbs

Capacity & Containers

Storage capacity:

up to 450 source containers (50 ml)

refrigerated

Containers:

Conical Sarstedt tubes

0,5–2,0 ml with lids

Software & Interfaces

Software

:

Windows-based, user management, audit trail

Interfaces:

:

ERP- and LIMS integration