SAFE® Tube Laser Marker

Precise laser coding for secure and unambiguous sample identification

Individual marking instead of rework.

The SAFE® Tube Laser Marker brings a new form of sample identification to the laboratory: fast, contactless and highly precise. Tubes are processed directly in the rack and marked with clearly structured codes that remain reliably readable at all times – ideal for digital workflows, automated systems and lab-wide traceability.

Whether in research, diagnostics, biobanking or regulated environments:

Direct laser coding creates permanent, clearly identifiable samples and reduces manual errors as well as labeling effort to a minimum.

SAFE® Tube Laser Marker

Precise laser coding for secure and unambiguous sample identification

Individual marking instead of rework.

The SAFE® Tube Laser Marker brings a new form of sample identification to the laboratory: fast, contactless and highly precise. Tubes are processed directly in the rack and marked with clearly structured codes that remain reliably readable at all times – ideal for digital workflows, automated systems and lab-wide traceability.

Whether in research, diagnostics, biobanking or regulated environments:

Direct laser coding creates permanent, uniquely identifiable samples and reduces manual errors and labeling effort to a minimum.

Your benefits at a glance

Permanent marking

Resistant to moisture, cold and abrasion — ideal for storage and transport.

Clearly readable codes

Clean, high-contrast markings for scanners, automation and digital documentation.

High processing speed

Up to 500 tubes per hour, ideal for high-throughput and serial workflows.

Flexible, customized code design

IDs, date, batch, text, symbols — freely configurable and immediately implementable.

Perfect for automated laboratories

Compatible with digital sample tracking, LIMS, screening platforms and robotic systems.

Why a laser marker? – Advanced labeling for modern laboratories

The Data Matrix code on the tube bottom has been an important standard in sample management for years and has significantly simplified automated handling.

However, many laboratories now require additional, clearly readable information directly on the tube – such as study identifiers, batch IDs, work lists or project-specific markings.

To avoid manual labeling, adhesive labels and error-prone ad hoc solutions, the SAFE® Tube Laser Marker was developed.

It enables fully automated, flexible and permanently readable direct marking that fits perfectly into digital laboratory processes, screening workflows and automated platforms.

Precise. Permanent. Traceable.

With clearly readable codes, fast processing of up to 500 tubes per hour and flexible design of IDs, text or symbols, direct laser coding is the perfect building block for digital workflows, automated platforms and lab-wide traceability.

See how the SAFE® Tube Laser Marker permanently applies individual information to each tube – resistant to cold, moisture and mechanical stress.

Ideal for biobanking, diagnostics, research, screening and all areas where samples must be identified clearly, securely and in a standardized way.

Application & workflow

The laser marker processes SAFE® tubes in all common SBS formats (96, 48, 24) and automatically codes them directly from the rack — including double marking if required.

Workflow overview:

The result: standardized sample identification with high speed and maximum readability.

Typical areas of application

SAFE® Tube Laser Marker

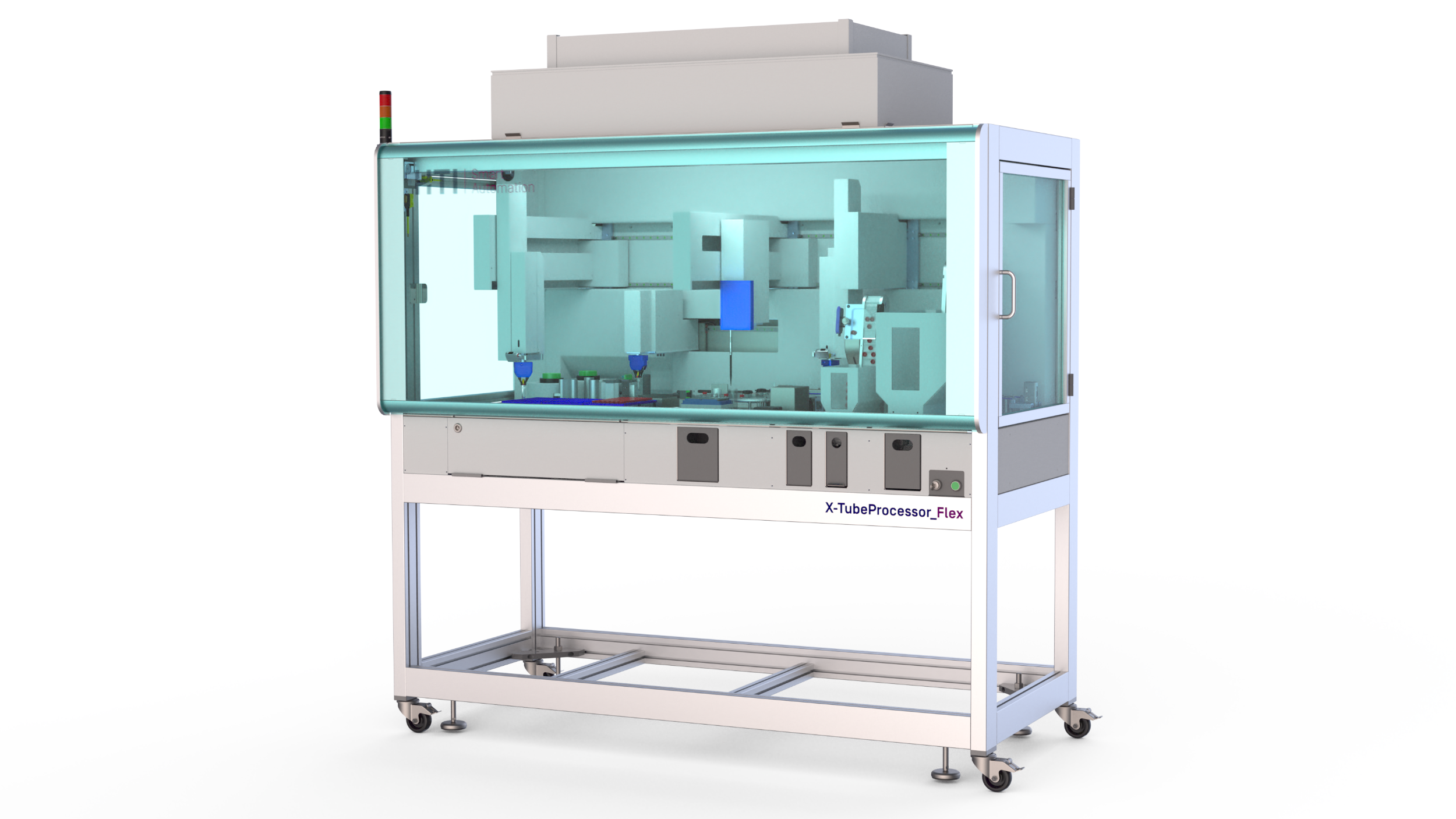

Dimensions and weight

Dimensions:

Approx. 35.8″ × 32.1″ × 28.3″ (H × W × D)

910 × 815 × 720 mm (H × B × T)

Weight:

Approx. 265 lbs

ca. 120 kg

Technical data & highlights

Technical data

Power supply: 100–240 V, 50/60 Hz,

max. 16 A at 230 V

Noise level:<72 dB(A)

Loading positions: 9 SBS/ANSI racks

Supported rack formats: SAFE® SBS 96, 48, 24

Throughput: up to 500 tubes per hour

Data exchange: CSV format

Technical highlights

Speed: up to 500 tubes/h

Formats: compatible with SAFE® SBS 96, 48 and 24

Double-sided laser coding

Automatic detection of 9 racks

Touchscreen operation

Flexible code design via PC software

CSV data import & export

SAFE® rack compatibility