X-TubeProcessor®

Smart 2.0

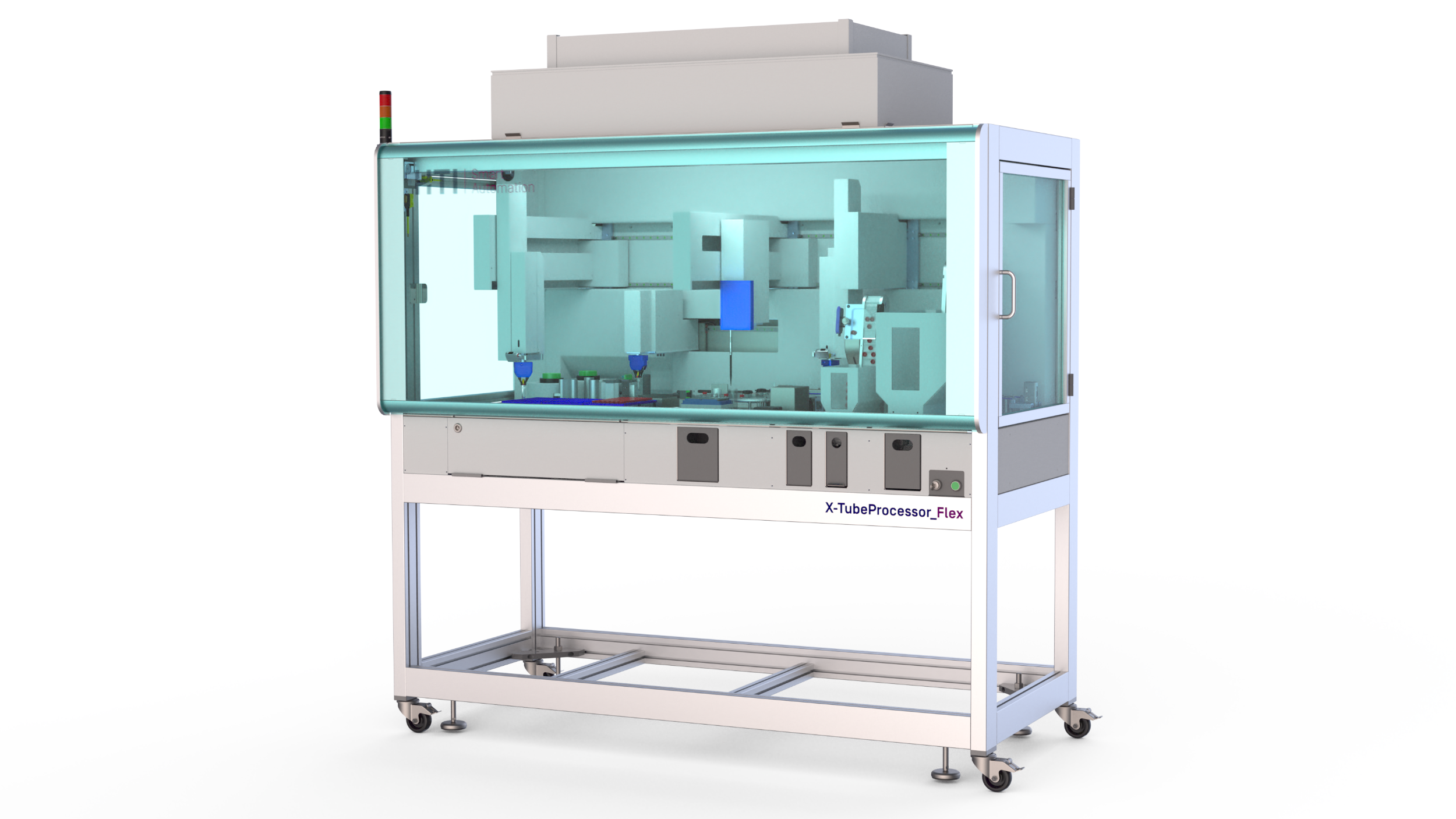

Compact 3-in-1 automation for flexible tube processing — now with X-Control.

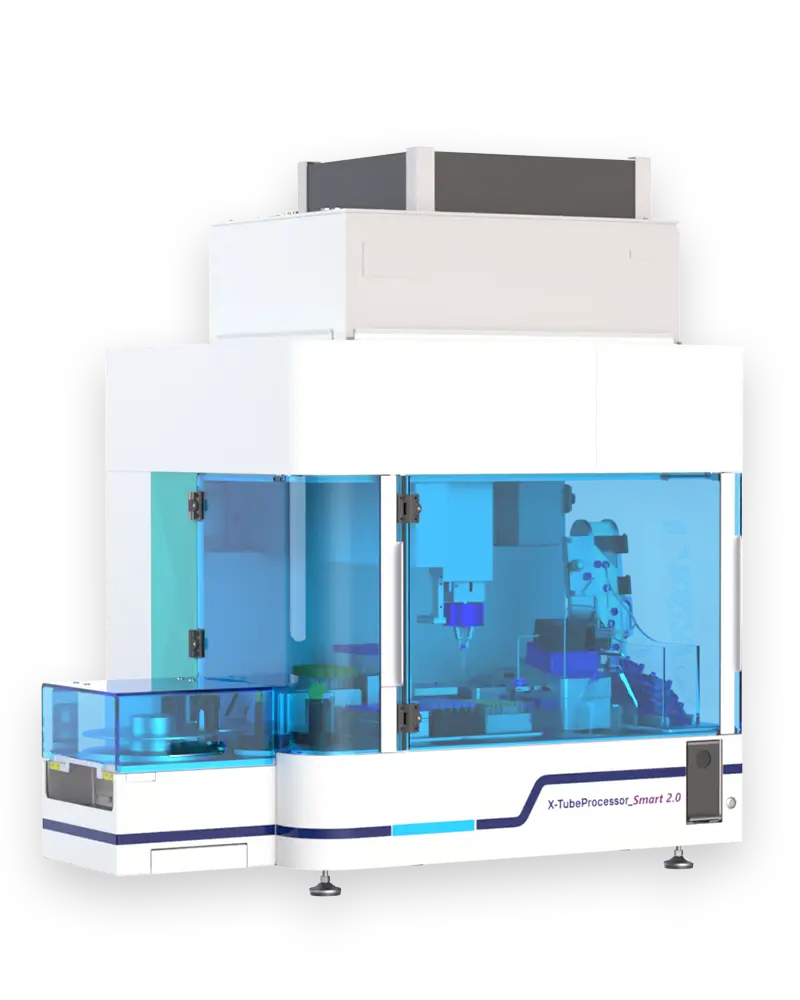

The X-TubeProcessor®_Smart 2.0 is the next generation of compact laboratory automation — dispensing, labeling, and capping in a single system. It combines proven precision with key innovations:

It now processes tubes and vials in the volume range of 0.5–15 ml without any gripper change, supports different and configurable workflows, and – with the X-Control software – offers numerous new functions in the areas of user management and audit trail for operation in regulated environments.

In combination with the TwinCode barcoding system, the Smart 2.0 now enables tube-specific dispensing and labeling as well as seamless traceability of every single tube.

With a footprint of less than < 1 m², capacity for up to 6 SBS-format racks, and a processing speed of up to 370 tubes per hour, the Smart 2.0 is the ideal solution for laboratories looking to increase efficiency, traceability and reproducible quality – from routine applications to QC, from diagnostics to biotech.

The return on investment is typically achieved in under two years – based on an average reduction of manual work by 4 hours per day for 2 employees.

What’s new with the Smart 2.0?

The Smart 2.0 is based on the proven Smart system and has been newly equipped with the X-Control software. It enables greater flexibility in terms of supported tube and vial formats while simultaneously providing extended process and processing control. In addition, hardware options such as TwinCode and the choice of a microannular gear pump ensure increased precision and adaptability to the workflow – especially for regulated and digitally integrated laboratory environments and specialized dispensing requirements.

The Smart 2.0 is more than just an upgrade. It has been specifically designed for greater flexibility and simple, intuitive operation, and supports workflows in regulated laboratory environments far more comprehensively than its predecessor.

Laboratories benefit from clearly structured workflows, high user-friendliness, and a noticeable reduction in manual work by several hours per day.

Proven automation in molecular diagnostics

At PathoFinder, the X-TubeProcessor®_Smart is used in core production workflows for dispensing, labeling, and capping under strict quality requirements.

The system supports reliable, traceable processes while significantly reducing manual supervision and freeing skilled staff for higher-value tasks.

This enables PathoFinder to increase capacity and prepare for future growth without compromising quality.

Automation in the smallest footprint – flexible and reliable

With the X-TubeProcessor®_Smart 2.0, you automate time-consuming routine processes related to screw-cap tubes: From precise dispensing to secure capping/decapping and validated labeling, the system performs complete workflows without manual intervention. The optional HEPA filter ensures a sterile working environment.

Here’s how the X-TubeProcessor®_Smart 2.0 works, step by step:

Load tubes

Up to 6 SBS racks simultaneously—for long walk-away times and high productivity.

Automatic opening & closing

Capping and decapping of 0.5–15 ml tubes & vials with Torque control and rotational movement monitoring for reproducible results. .

Precise filling

Optional peristaltic pump or micro annular gear pump. Routine functions are controlled via the DosingPumpManager.

Labeling & validation

Automatic positioning and labeling; optional label verification via TwinCode. Label templates with dynamic additional information (lot no., expiry date); can be used as a network printer.

Sort & Store

Structured downstream processing and storage of tubes – ideal for serial and batch workflows.

X-Control

Intelligent, auditable job & process management: planning, documentation, and control of all workflows – locally or remotely.

Voices from the field

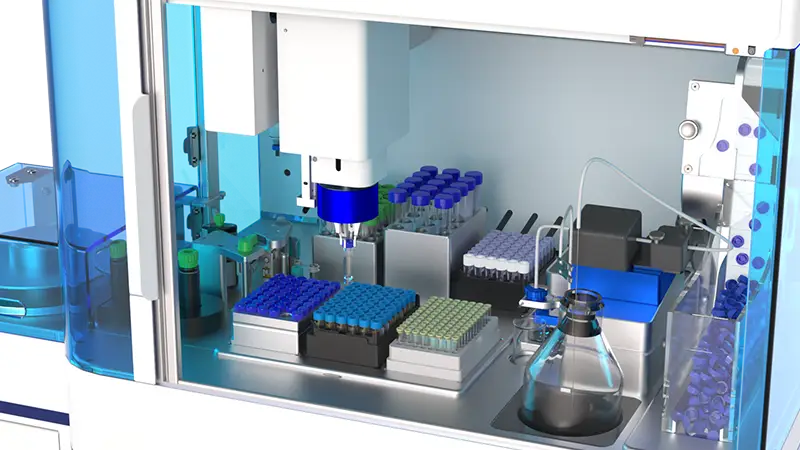

All functional modules of the Smart 2.0

Tube Handling incl. Capping & Decapping

Automated opening and closing of a wide range of tubes and vials from 0.5 to 15 ml. Monitoring of rotational movement ensures reproducible results and reduces manual errors – independent of tube size and application.

Precise dispensing with two pump technologies

Depending on application requirements, either a peristaltic pump for dispensing without media contact with fast tube changes, or an optional micro annular gear pump for maximum dosing accuracy and stability is available. Both pumps are centrally controlled via the DosingPumpManager, including priming, cleaning, and calibration functions.

Labeling with flexible templates and in-process control

High-resolution, automated labeling with precise positioning. Support for label templates with fixed or dynamic content (e.g. lot number, expiry date), as well as use as a network printer for existing Bartender files. Optionally, TwinCode enables additional label verification during the process.

X-Control Software – Central workflow control

Centralized job and process management for planning, control, and documentation of all workflows. X-Control supports audit trail and reporting functions and can be seamlessly integrated into existing LIMS and ERP systems via REST APIs.

Tube-specific processing and traceability with TwinCode

Processing of bottom and side barcodes for tube-specific control of dispensing, labeling, and in-process controls. All process data is uniquely assigned to each individual tube and documented in an exportable job log file – ensuring complete traceability and supporting GLP and GMP processes.

Result:

Standardized processes, reproducible results, and a compact all-in-one solution that measurably increases efficiency and quality.

X-Control – support for maximum control and compliance

X-Control turns the Smart 2.0 into an intelligent platform for controlled, transparent, and standardized workflows. The software provides features that support users in implementing GMP-, GLP-, and 21 CFR Part 11–relevant processes.

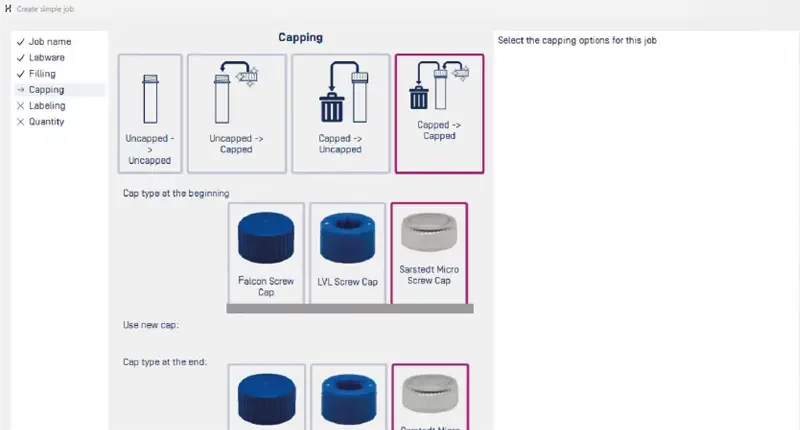

Job Creation

Intuitive creation of new workflows in under three minutes – locally or remotely.

- Clear, logically structured process steps (dispensing, capping, labeling, barcode)

- Recipe functions & variable inputs (number of tubes, fill volume, etc.)

- High flexibility through combinable process steps

- Job templates for standardized and reproducible workflows

- Support for various tube & vial types as well as liquid classes

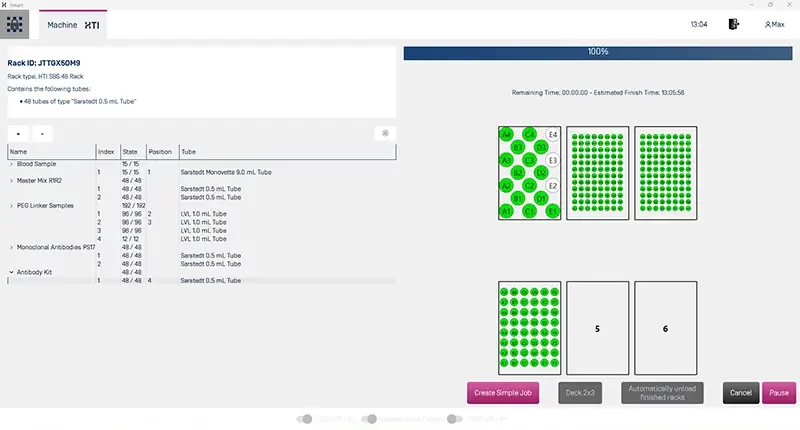

Job Management

Plan, manage, and execute workflows – on the device or remotely.

- Color status system (green/blue/red) for job status and required labware

- Management of all components: racks, tubes, labels, caps

- Data import from Excel, ERP, or LIMS

- Seamless system integration via REST API

- Ideal for end-to-end digitization and automated routine workflows

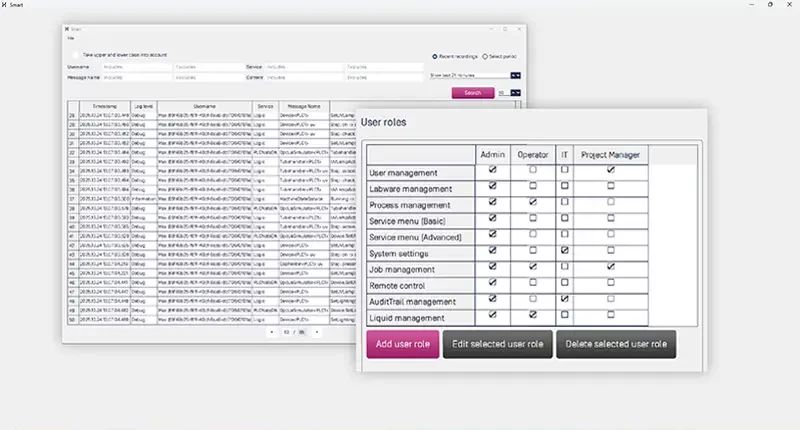

Control & governance

Compliant and traceable process execution.

- User management: roles & permissions for clear, documented governance

- Audit trail & LogViewer: complete logging of all actions with timestamps

- Export functions (PDF/CSV) and optional database access for in-depth analysis

- System information: notifications, statistics, device status & language settings

- Maximum transparency for regulated laboratory environments

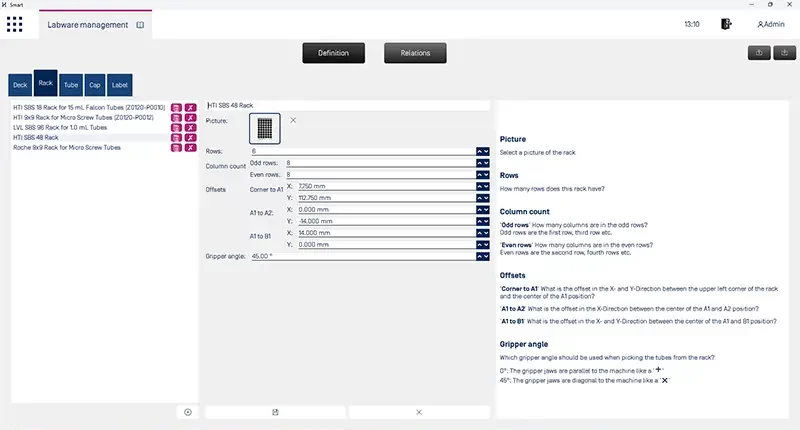

Labware & Pump

Centralized management of all labware and pump processes

- Management of racks, tubes, caps & labels

- LWM Pro: Flexibles Erstellen neuer Labware-Definitionen

- Dosing Pump Manager: priming, cleaning & calibration of the pump

- Management & creation of custom liquid classes

- Teaching Wizard for fast onboarding of device-specific components

Areas of application:

The X-TubeProcessor®_Smart 2.0 is ideal for laboratories looking to automate repetitive routine processes, reduce manual errors, and simultaneously increase flexibility, transparency, and process reliability – particularly for small to medium volumes.

It is particularly suited for applications where:

Typical fields of application:

The Smart 2.0 is used, among others, in:

Diagnostics · Life science services · Biotechnology · Pharma · Environmental laboratories · Biobanking · Research & Development · QC laboratories

Benefits of laboratory automation with the X-TubeProcessor®_Smart 2.0

Technical specifications & performance features

Info Download

Supported tubes & vials

Volumes: 0.5–15 ml

Diameter: 7–22 mm

Height: up to 65 mm

Compatibility includes: Sarstedt, Greiner, Thermo Fisher, SSI, Biozym, cryovials, biobank tubes, HPLC vials, FACS tubes, blood collection tubes, conical tubes (others available on request)

Dimensions and weight

Dimensions:

Approx. 32.3″ × 28.7″ × 33.1″ (W × D × H),

with HEPA filter 45.3″ height

ca. 82 × 73 × 84 cm (B × T × H),

with HEPA filter 115 cm height

Weight:

Approx. 158.7 – 209.4 lbs (depemdimg on configuration)

ca. 72–95 kg (konfigurationsabhängig)

Speed and capacity

Speed

Up to 370 tubes per hour (depending on workflow)

360 tubes/h labeling

303 tubes/h dispensing + capping

180 tubes/h 3-in-1 processing

Capacity:

Supply: 576 micro screw tubes

Storage: 1,152 microvials

6 SBS racks in parallel